SLB

Solving industry’s most pressing challenges.

Ensuring the sustainability, security, and equity of energy access means we must think big. We need global solutions that can be scaled and adopted quickly. SLB’s know-how and technology are helping to overcome industry’s greatest challenges while transforming energy.

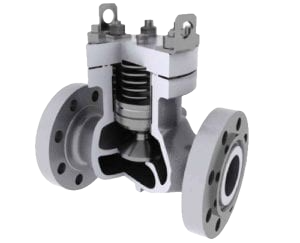

- TOM WHEATLEY Piston Check Valve

- TOM WHEATLEY Swing Check Valve

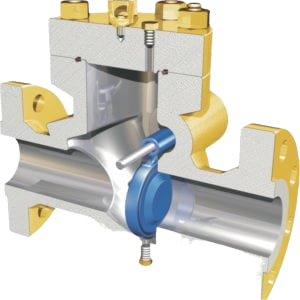

- WHEATLEY Series 500

- WHEATLEY Series 822

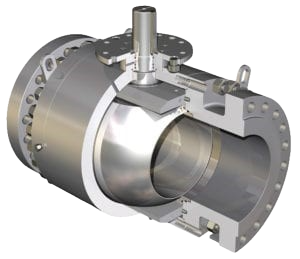

- WKM 370D5

- WKM 370D6

A unique non-slam design.

Due to a unique non-slam design, the Cameron TOM WHEATLEY piston check valve has provided years of uninterrupted service downstream from reciprocating pumps and compressors, and in other applications where conventional check valve designs would be subjected to excessive wear. The valve’s top-entry design allows for easy access and replacement of all valve internal parts with reduced downtime.

Prevents backflow in a fraction of a second.

The Cameron TOM WHEATLEY swing check valve is used in critical service applications worldwide. The swing check design prevents backflow in a fraction of a second and there is no need for expensive actuation. The TOM WHEATLEY swing check valve’s subsea model features a unique, free-swinging clapper. If a reverse flow or critical pigging operation is required, the clapper can be manually, ROV, or hydraulically actuated and held in a full open position.

Reduces installation guesswork.

The Cameron WHEATLEY Series 500 check valve is a fire-tested carbon steel flanged end check valve with a full-open, through-conduit design for low pressure drop and less turbulence. The valve’s flanges are back-faced. This is an extra manufacturing step that provides smoother bolting surfaces and even bolt loading.

Bubble-tight primary seal.

The Cameron WHEATLEY Series 822 check valve is designed to safely prevent backflow of liquid or gas in pipeline applications. The valve’s beveled, self-aligning clapper and seat design incorporates a molded seal in the clapper for a bubble-tight primary seal and metal-to-metal secondary seal.

Three-piece forged construction.

The Cameron WKM D Series ball valves satisfy a wide range of ANSI and API 6D applications. Engineered for heavy-duty, reduced-maintenance performance and manufactured in a variety of body and seal materials. The WKM D Series valves are commonly selected for many specialized applications such as gas distribution, gas transmission, oilfield production, and industrial applications.

Trunnion-mounted ball valve.

The WKM D Series ball valves satisfy a wide range of ANSI and API 6D applications. Engineered for heavy-duty, reduced-maintenance performance and manufactured in a variety of body and seal materials. The WKM D Series valves are commonly selected for many specialized applications such as gas distribution, gas transmission, oilfield production, and industrial applications.