TMCO

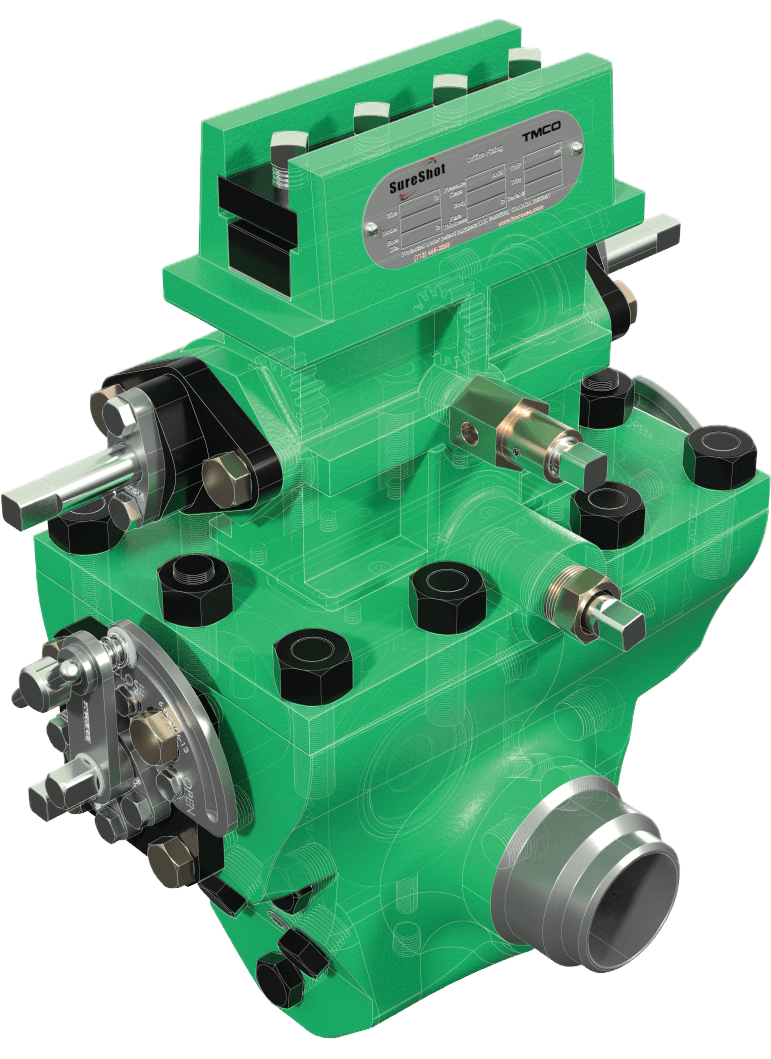

The SureShot® Family of Orifice Fittings.

For decades, TMCO has worked within the energy and process control industries to optimize results in measurement and control with operationally excellent meters.

- Sureshot Dual Chamber Fitting

- Sureshot Single Chamber Fitting

- TrueShot UIM-3/3F

- TrueShot UIM-4F

- FMR 150

- Compact Provers

- Large Volume Provers

- Calcube Modular Provers

The SureShot Dual Chamber is TMCO’s flagship fitting.

Customer-driven design features ensure safe, cost-effective, and operationally excellent solutions to the most demanding gas measurement challenges.

SureShot Dual Chamber Orifice fittings fully conform to the latest AGA 3/API 14.3 stringent requirements. They require no added uncertainty and provide accurate performance over the orifice plate beta ratio range from 0.1 to 0.75 within 0.5% flow accuracy to theoretical value.

A rugged, field-proven unit that does the work easily, reliably, and safely.

SureShot Single Chamber Orifice fittings fully conform to the latest AGA 3/API 14.3 stringent requirements. They require no added uncertainty and provide accurate performance over the orifice plate beta ratio range from 0.1 to 0.75 within 0.5% flow accuracy to theoretical value.

One piece body allows for quick, inexpensive orifice plate changes without the time-consuming operational steps associated with Orifice Flange Union.

Custody transfer accuracy at economical cost.

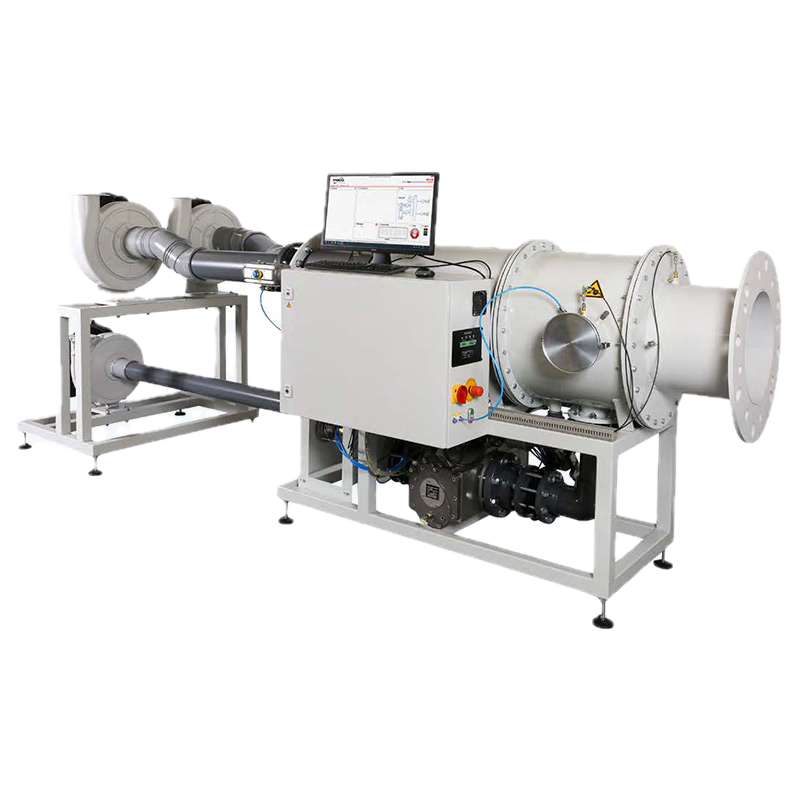

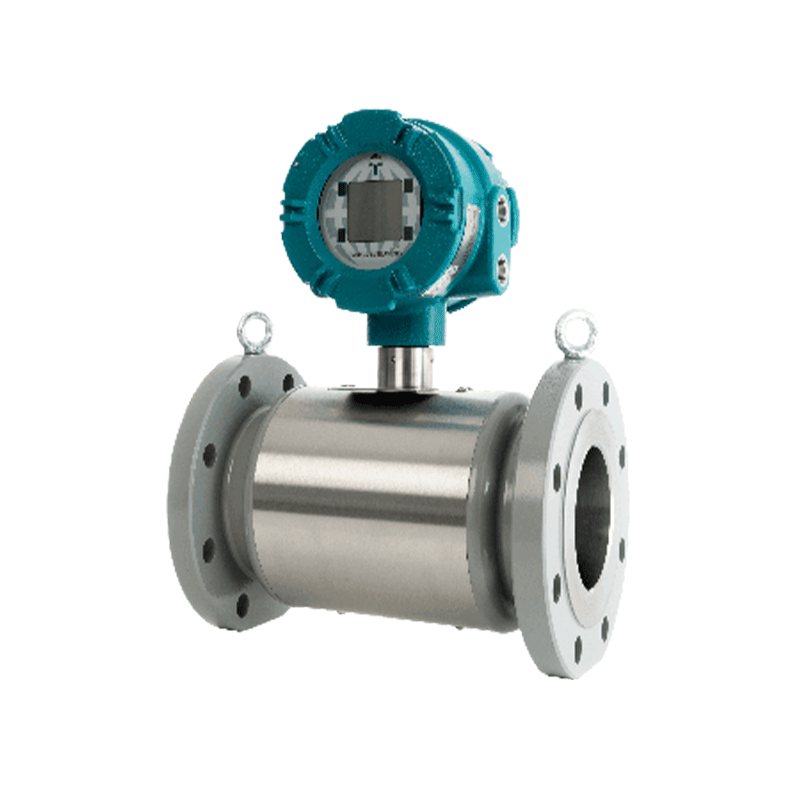

Today there is an increasing need to monitor emissions and improve energy efficiency in order to meet new environmental and economic challenges. These gases are usually dirty and wet and they can contain corrosive gases and liquids. Until now, there have been no suitable flowmeters for many of these applications. The new UIM-3/3F ultrasonic flowmeters use patented Broadband Continuous Wave© signal processing and high efficiency titanium transducers to provide reliable and precise flow measurement even in the most extreme applications.

Tested to meet international standards.

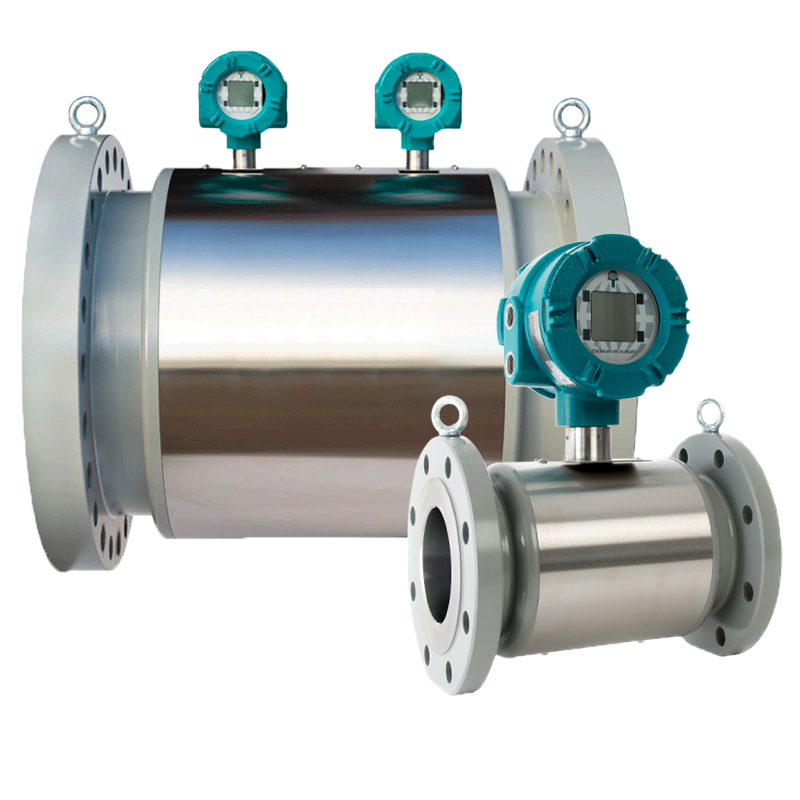

The UIM-4F has four paths as standard It has been tested to meet the international standards for custody transfer metering including AGA-9 and OIML R137 (class 0.5). Integration of the flow across the paths provides accurate measurement even with varying flow profiles caused by changes in flow velocity, gas composition and pressure or upstream pipe configuration.

The UIM-4F Duo consists of two fully independent systems. The main measurement is done by the UIM-4F four path part. The three path system provides a secondary measurement and uses enhanced diagnostics to enable the user to perform condition-based maintenance. In addition, the UIM-4F Duo provides a wealth of information on the condition of the complete metering system.

Tested to meet international standards.

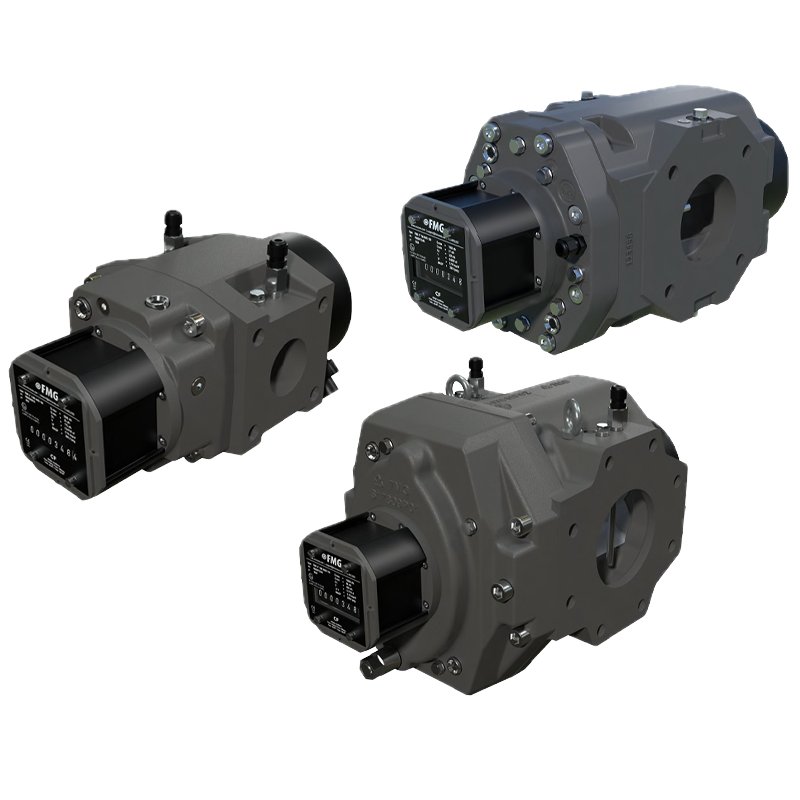

The Rotary Meter Series is designed to accurately and reliably meet the highest demands of gas flow measurement. Meters are MID approved and fully comply with ANSI B109.3 and OIML R137. The compact exchangeable aluminum cartridge allows local repair and on-site cleaning. The robust design of the casing and cartridge make the meter less sensitive to installation stresses caused by the connecting piping. The entire aluminum casing is designed for working pressures up to 290 psig with a safety factor of 4.

Meters are more resistant to overload and pressure shocks because of the improved

position of the main bearings and shafts and square impellers. The aluminum index and the protection of the standard installed, low frequency reed contact with the associated magnets, make the meter more resistant to tampering or manipulation.